New catalog - more items added daily!

- Rewards

Program - About

- Contact Us

- (800) 562-8375

- Account

- Cart

Return

Print

Email

PFERD 47801601 by PFERD

Call For Price

- Part Number: 47801601

- UPC:

- Availability:

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

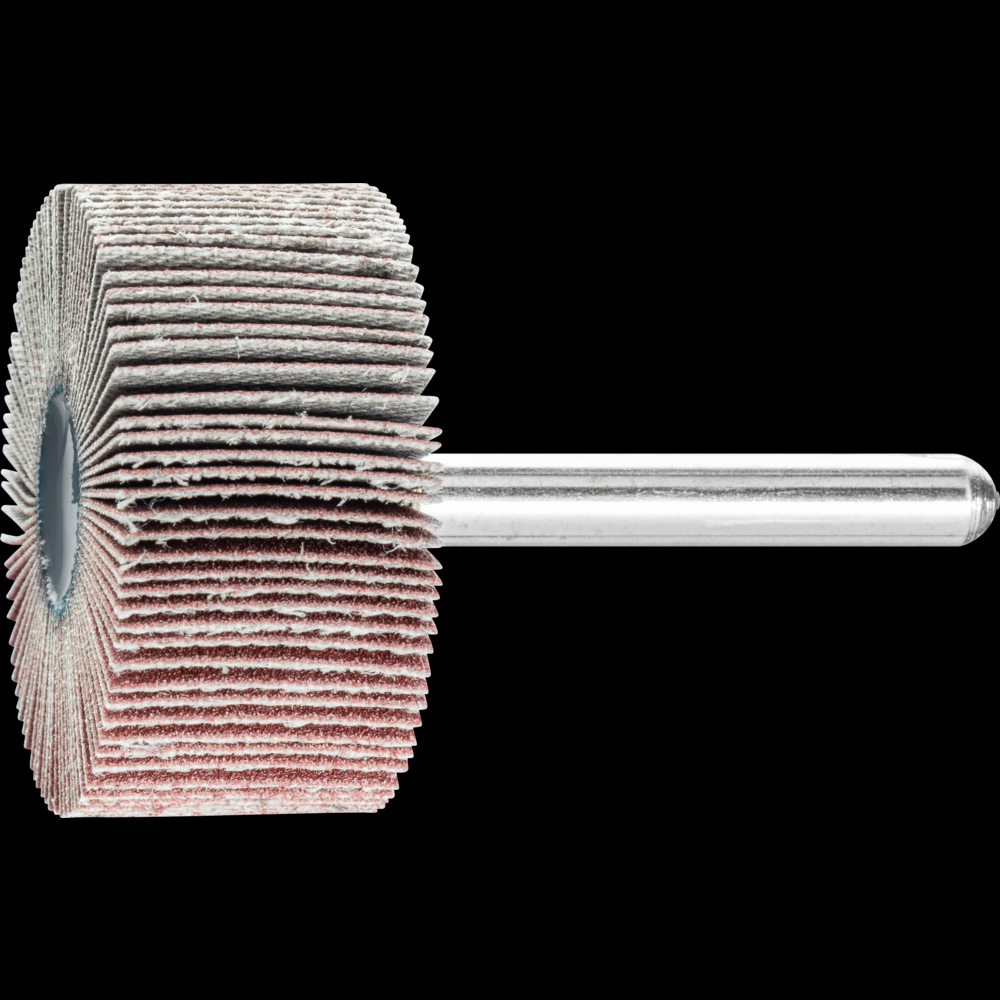

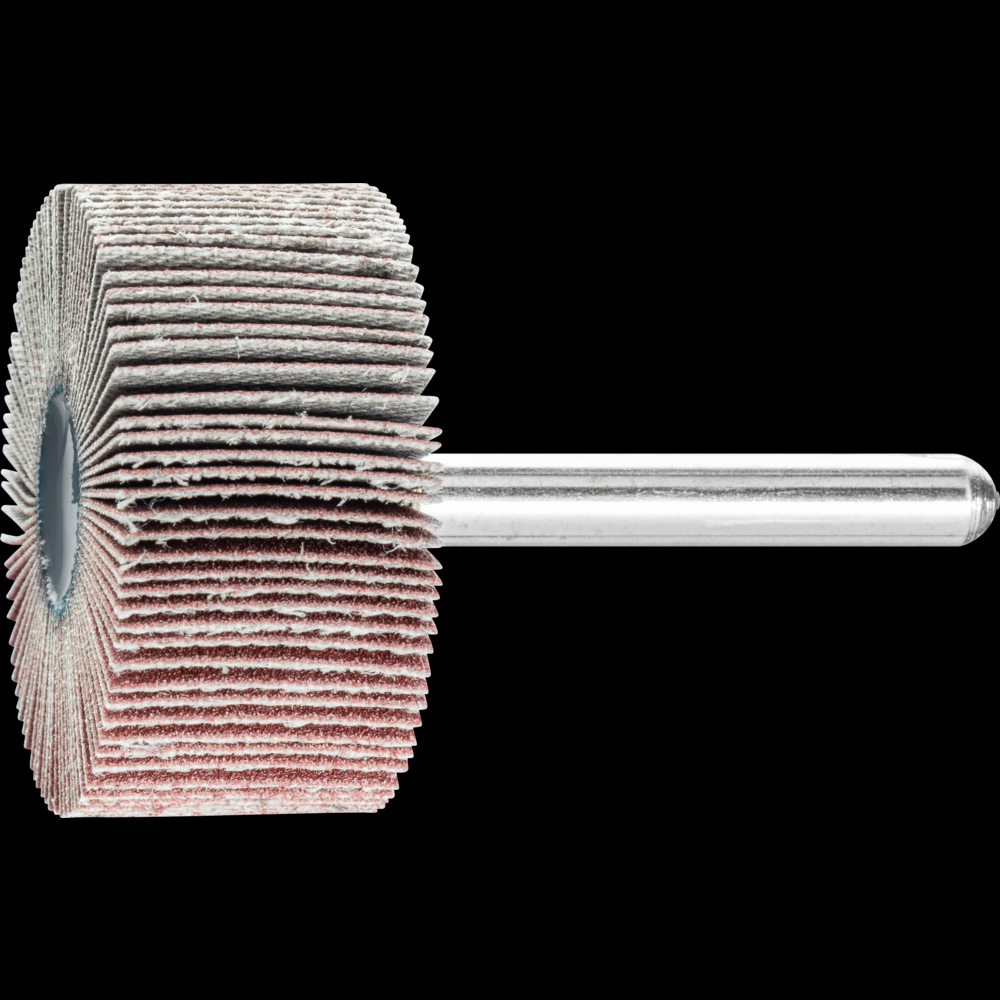

PFERD Mounted Flap Wheel, 1-1/2" x 1, 180 Grit, 1/4" Shank, Aluminum oxideWith mounted flap wheels, coated abrasive flaps are arranged radially around the core in a fan-like structure. The flexible flaps perfectly adapt to surface contours. The abrasive grain is embedded in the sturdy, flexible cloth backing material with a resinoid bond. In ISO 3919, mounted flap wheels are designated as "flap wheels with shaft." For universal applications from coarse to fine grinding.

Specifications

Details

Category:

Abrasives

Subcategory:

Flap Wheels

Subtype:

Mounted Flap Wheels

Abrasive:

Aluminium oxide A

Advantages:

Conforms to contours due to high flexibility.

Advantages 1:

Consistently high stock removal rate throughout the entire service life as new, aggressive abrasive is constantly exposed.

Advantages 2:

Can be used face-down very close to edges and in corners thanks to the flat, moulded-core design.

Applications:

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Structuring (matt finishing, brush matting and satin finishing)

Applications 4:

Surface work

Applications 5:

Work on weld seams

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

ES

CUSTOMS_NUMBER:

6805100000

DEPTH:

0.109

Dia. external:

1 1/2

Dia. external UNIT:

Inch

Dia. shank:

1/4

Dia. shank UNIT:

Inch

Drive types:

Flexible shaft drive

Drive types 1:

Straight grinder

EAN pcs.:

4007220301425

EAN type:

AR

Grit size:

180

Gross weight (Piece):

0.04

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

109

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (ean):

4007220448724

INTERNATIONAL_PID (edp):

45235

INTERNATIONAL_PID (gtin):

4007220448724

INTERNATIONAL_PID (upc):

97758452359

KEYWORD:

Coated abrasives

KEYWORD 1:

Mounted flap wheels

KEYWORD 2:

Aluminum oxide A

LEADTIME:

3

LENGTH:

0.129

Length (Packaging unit):

129

Length (Packaging unit) UNIT:

mm

Length, shank:

1 1/2

Length, shank UNIT:

Inch

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

47801601

MANUFACTURER_TYPE_DESCR:

F 4125 6,35 A 180

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Annealed cast iron

Materials that can be worked 2:

Brass

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Copper

Materials that can be worked 5:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 6:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 7:

Stainless steel (INOX)

Materials that can be worked 8:

Steel materials with a hardness > 54 HRC

Materials that can be worked 9:

Steels up to 370 HV (< 38 HRC)

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD Mounted Flap Wheel, 1-1/2" x 1, 180 Grit, 1/4" Shank, Aluminum oxide

PFERDERGONOMICS:

PFERDERGONOMICS recommends mounted flap wheels to reduce vibration and noise produced during use and to improve comfort when working.

Product issue name web for bmecat:

Mounted flap wheels

PRODUCT_ORDER:

300

prop65:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

10

QUANTITY_MIN:

10

Recommendations for use:

Flap wheel wear and the thermal load on the workpiece are reduced by decreasing the contact pressure and peripheral speed, and by adding grinding oil.

Recommendations for use 1:

Stock removal rate should be increased by using a coarser grit, not by increasing the contact pressure. This avoids unnecessary flap wheel wear and prevents the thermal load of the workpiece.

Recommendations for use 2:

Increasing the speed results in a slightly finer surface quality. An increase in contact pressure results in a slightly coarser surface. The softer the workpiece material, the coarser the resulting surface (when using the same grit size).

Recommendations for use 3:

For the best performance, use with a recommended peripheral speed of 3,000-4,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and tool wear.

Recommendations for use 4:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

REFERENCE_FEATURE_GROUP_ID:

P_16005_179733

RPM, max.:

23000

RPM, max. UNIT:

RPM

RPM, optimum:

9600

RPM, optimum UNIT:

RPM

Safety notes:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Safety notes 1:

The contact pressure has to be reduced significantly when the optimum rotational speed is exceeded.

Safety notes 2:

Ensure the clamping depth is at least 5/8" and the specified maximum rotational speed is not exceeded with unsupported shank lengths.

SEGMENT:

Fine grinding and finishing products

SPECIAL_TREATMENT_CLASS:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

UNSPSC 25.0901:

31191600

UPC pcs.:

0

UPC type:

UC

UPC VE:

97758452359

VOLUME:

0.001078

Volume (Packaging unit):

1078

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.04

WIDTH:

0.109

Width:

1

Width (Packaging unit):

109

Width (Packaging unit) UNIT:

mm

Width UNIT:

Inch

Manufactured By:

PFERD